GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

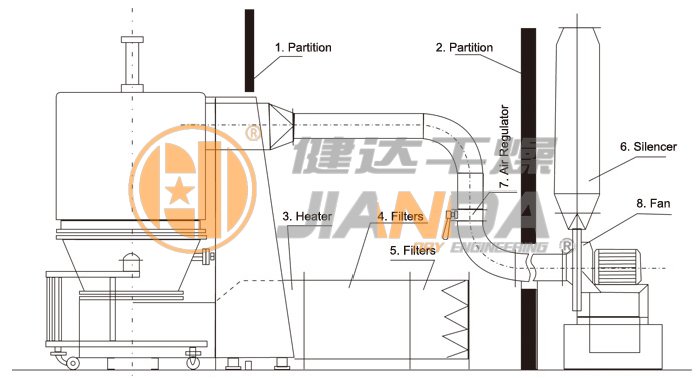

WORKING PRINCIPLE

The purified and heated air is introduced from the bottom by the draft fan and passed through the screen plate. The fluidization is formed through stirring and negative pressure in the working room. The moisture will be rapidly evaporated and exhausted so the material can be dried very fast.

FEATURES

1) The structure of fluidization bed is round so it is smooth inside without cleaning dead corners.

2) There is a stirring device inside of the hopper which can avoid agglomeration of wet material.

3) The granule is discharged by tipping over the hopper. The discharged system can be designed as per customer requirements.

4) The dryer is operated at the negative pressure and seal conditions. The air is filtered before enters to the dryer. Therefore, it is simple in operation and convenient in cleaning.

5) The drying speed is fast and the temperature is uniform. The drying time is normally 20~30 min utes for each batch.

APPLICATION

This dryer is widely used for the following materials:

1) Damp granules and powder materials in pharmaceutical, foodstuff, feed, chemi cal, and agrochemical industries.

2) Granules made by extruder, oscillating granulator, and high speed mixing granulator.

3) Special large granule and small blocks that having adhesive property.

4) The material that changes volume during drying process; such as konjak.

PRODUCTION PARAMETERS

TECHNICAL PARAMETERS

| Item | Model | ||||||

| Feeding Capacity (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan Power (kw) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Stirring Power (kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Stirring Speed (rpm) | 8~11 | ||||||

| Steam Consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Working Time (min) | 15-30(It depends on the nature of materials) | ||||||

| Dryer Heigh (mm) | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

-

GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

-

GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

-

GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

-

GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

-

GFG High-Efficiency Fluidizing Dryer (Fluid Bed)

- 2020-03-14 > Subverting the industry, Daikin polymer aluminum chloride drum scraper dryer

- 2019-12-31 > Quit the old 2019 and look forward to 2020

- 2019-12-30 > Jianda Boiling Dryer sent to Chicago, USA

- 2019-12-05 > Four process design methods of rotary flash dryer

- 2019-11-16 > Potassium sulfate disc dryer delivered on site and put into use

- 2019-11-14 > Analysis on the Application of Eight Drying Equipments in Chemical and Pharmaceutical Industry

- 2019-10-18 > Anhui Red Sifang Co., Ltd. ordered our company's "sodium formate drying production line"

- 2019-10-16 > Application of spray drying desulfurization technology in protecting ecological environment

- 2019-09-30 > Common failures and maintenance of belt dryers during use

- 2019-09-30 > Jiangsu Jianda Drying welcomes the 70th anniversary of National Day